No. 151, 11th Main, Peenya Ind Area

Laggere, Bangalore -560 058

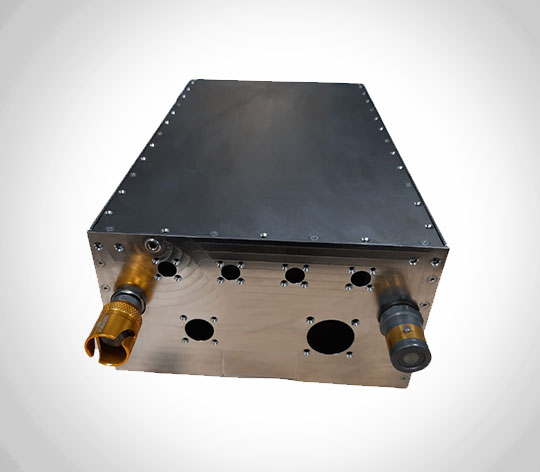

Rugged enclosure

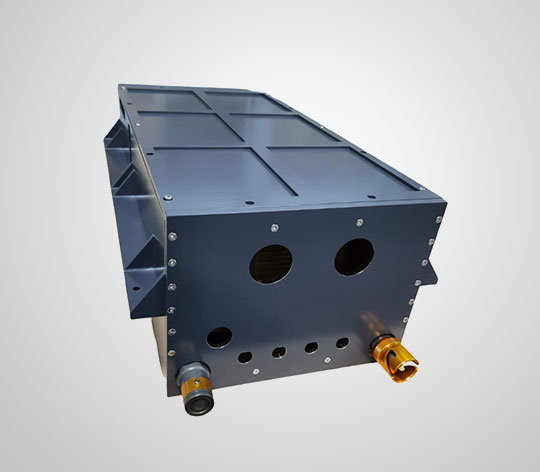

Rugged enclosure

- Additional surface area for improved heat spreading increases heat transfer away from thermal loads and to the chassis which dissipates heat to ambient air. Air cooledd chassis and enclosures can be designed for natural convection for rugged, high Reliability requirements or benefits from the addition of a fan or blower for air cooling. Protection and thermal management solution.

- Integrated enclosures or chassis that include thermal management technologies help engineers application size, weight and power (SWaP) consumption as their requirements become more stringent.

- Popular fabrication methods include aluminium machining, sheet metal bending, welding and vacuum brazing as well as integrating two phase or heat spreading technologies such as heat pipes and bi-metallic sinks.

- We are more frequently incorporating heat spreading, thermal joints and other technologies into enclosure designs so that these enclosures and chassis act as both a structural and thermal solution to replace traditional machined enclosures.